![]()

The best material in semiconductor manufacturing is highly durable, long-lasting, and resistant against high-heat environmentals and industial chemicals. Sapphire checks all these boxes.

A single crystral with high purity and impressive strength, sapphire is an excellent industry-accepted material for semiconductor manufacturing. Its scratch resistance makes it ideal for vacuum environments, and its high-plasma resistance withstands etching. Even the alkalis and acids used in the manufacturing processes of semiconductors won’t break down sapphire.

In this article, we’ll dive into sapphire’s specific applications, why it’s superior to quartz in semiconductor manufacturing, and Swiss Jewel’s sapphire product inventory.

Sapphire’s Applications

Because its properties suit semiconductor manufacturing, sapphire is used for many applications within the industry, including the viewports of etching apparatuses, ashing equipment, and diffusion furnaces. Sapphire tubes can successfully discharge the activated plasma gas used for etching.

Given its purity of 99.99%, sapphire is commonly used for parts and jigs in semiconductor manufacturing lines. It also suits semicondcutor process chambers, resisting high-temperature environments of up to 2,000°C, better than other materials.

Sapphire vs. Quartz

Quartz is another material commonly used in the semiconductor industry. While it has its benefits, sapphire is the superior choice for several reasons.

Process environments use aggressive chemistries that rapidly erode quartz windows with the quartz surface becoming cloudy. Extended exposure can lead to the complete erosion of quartz windows to the point of failure, either by full penetration or undercutting of sealing O-rings. Because of this, the service life of quartz windows can be quite limited.

Sapphire windows, on the other hand, can be used indefinitely. Sapphire’s strength, approximately six times greater than quartz, allows it to hold up in high-pressure environments. Sapphire windows are usually 30% to 50% of the thickness of the quartz window they replace, and they maintain their transparency much better than quartz. This makes sapphire the preferred choice for high-purity applications in semiconductor manufacturing.

Swiss Jewel’s Sapphire Inventory

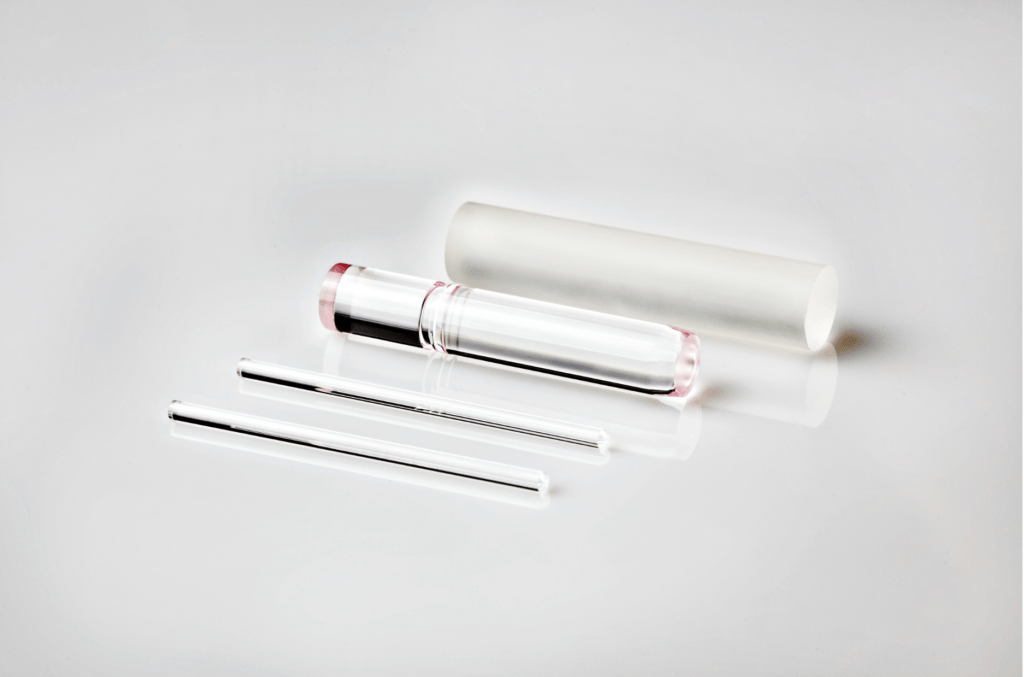

Looking for sapphire materials for your semiconductor machinery? Swiss Jewel offers sapphire components in many forms for semiconductor equipment applications:

- Sapphire Balls

- Sapphire Tubes

- Sapphire Window and Viewports

- Sapphire Injector Nozzles

- Sapphire Rods (Pins)

Not seeing exactly what you’re looking for? We also take custom orders and can create components that uniquely fit your needs. Some custom fabrication options include stepped edges and mounting features.

Contact us today, and a member of our team will work with you on your next order.